鼎力板式家具生产解决方案

-

柜门生产方案

橱柜门板自动化生产方案,包含板材反面贴标,反面打铰链孔,玻璃门背面加工,自动翻板,然后自动加工正面,最后机器人自动分拣等单元的自动化连线。

查看更多 -

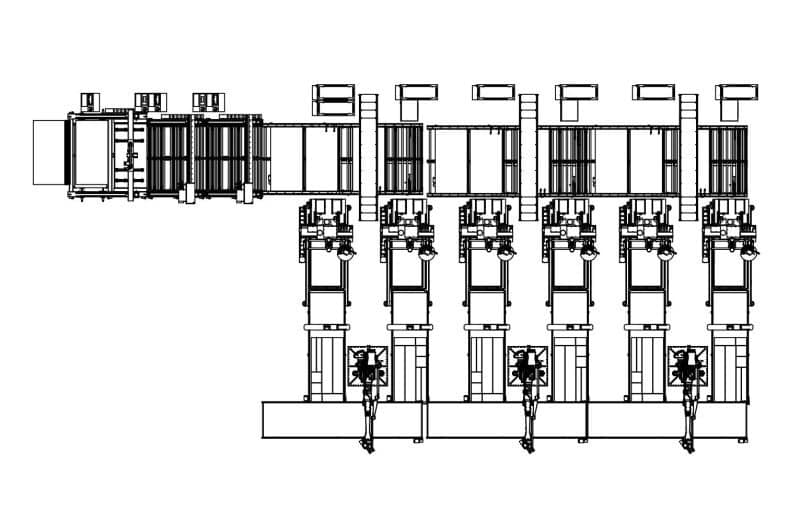

柜体生产方案

柜体定制家具生产方案,包括板材供料,自动贴标系统、板面加工系统、板材输送系统、板材加工系统、成品自动化分拣系统以及废料处理系统。鼎力自主开发软件对接,可根据客户需求提供自动化生产方案。

查看更多 -

鼎力加工中心

可用于板式家具生产,全丝杆传动,精度高,使用寿命长。鼎力自主研发无尘加工吸尘头,引领无尘自动化工厂新趋势。

查看更多 -

其他数控机械

包括配套木工机械如数控六面钻等。亦可定制用于金属加工等其他行业的数控雕刻设备。

查看更多

展会预告

- 展会名称:中国建博会(广州)

- 时间:2021年7月20日-2021年7月23日

- 展位号:10.1-14

- 展会地点:中国进出口商品交易会展馆

新闻中心

-

股权激励 共创共赢

南京帝鼎数控科技有限公司日前举行2020年度股权激励合伙人分红会议,并兑现上一年度分红…

2021-04-29 -

鼎力二托六柜体开料生产线…

鼎力二托六柜体生产线在成都双虎家具顺利上线!通过式双贴标机可服务于六台加工中心,上…

2021-04-28 -

成长的见证----让天下没有…

栉风沐雨十数年,继往开来砥砺行。站在2020的年终岁末,回望这不平凡一年,面对疫情和严…

2021-01-19 -

南京帝鼎隆重举行“元旦杯…

新年到来之际,南京帝鼎数控科技有限公司成功举办2021年“元旦杯”乒乓球比赛,活动旨在…

2021-01-19 -

校企合作 共创共赢

飒爽秋日,丹桂飘香。国庆、中秋双节喜相逢之际,南京帝鼎数控科技有限公司成功牵手南京…

2021-01-15

查看更多>